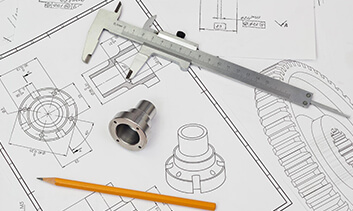

CNC machining

We have 25 years of experience in the field of machining. With our traditional and CNC machine tools, we manufacture the parts designed by our customers in small and medium serial numbers.

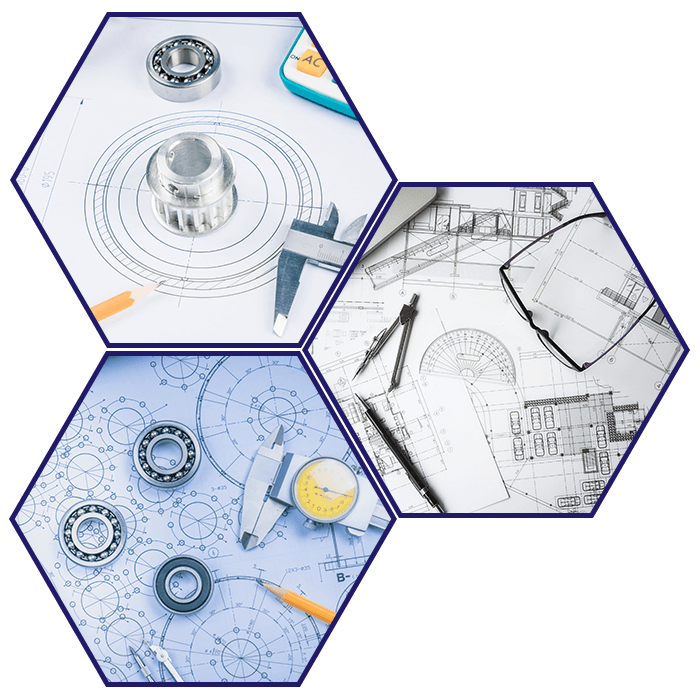

Engineering design

We offer individual solutions for individual needs. We undertake the design and implementation of special equipment and individual components that are responsible for the performance of a special task in production.

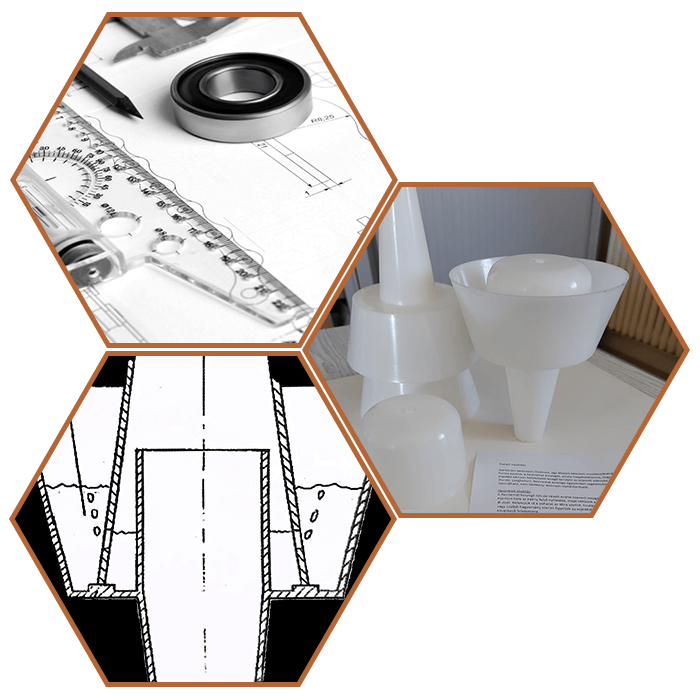

Prototype development

If you have an innovative idea, we will help you implement it! We are happy to support companies and individuals who have an innovative idea but do not have the resources to implement it.

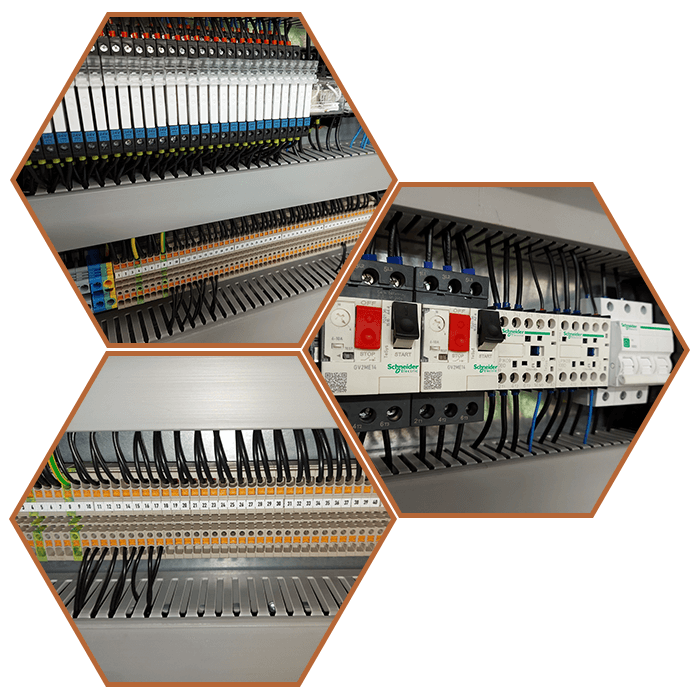

Electrical design

Our company undertakes the design, installation and programming of electrical controls for individual machines and equipment. Whether it is a completely new machine or the development of an existing machine, contact us with confidence.

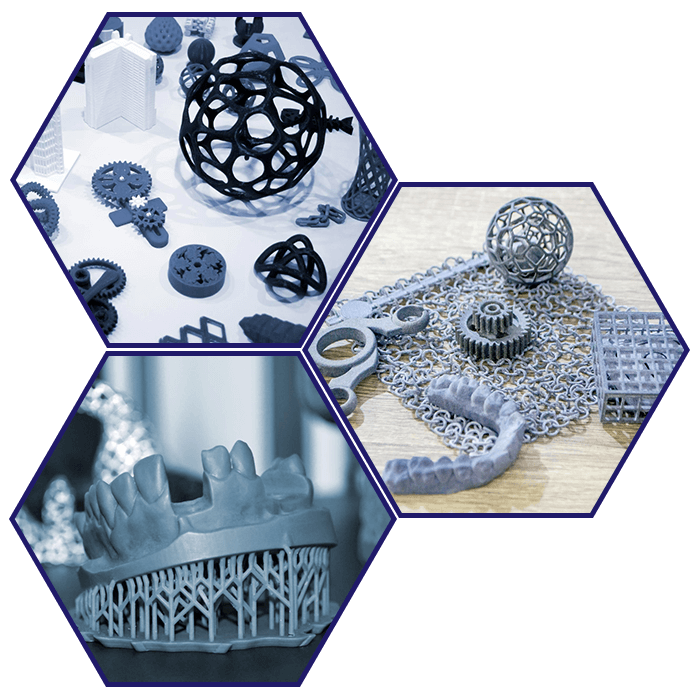

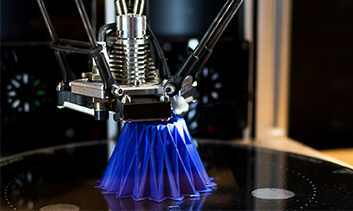

3D printing

3D printing is a revolutionary innovation in manufacturing technology. A big advantage of FDM 3D printing technology is that we are able to produce even complicated parts in a short period of time, for a fraction of the price of machining.